The most common faucet types include compression, cartridge, ceramic-disk, and ball-type. Compression faucets, the oldest among the types, employ a mechanism where a rubber washer seals against a valve seat to control water flow. This design is straightforward but requires regular maintenance as the washers wear out over time due to constant friction. Recognizing a compression faucet is relatively easy, as it typically has separate handles for hot and cold water, which need to be tightened to halt the water flow.

Cartridge faucets represent a more modern design where the flow of water is regulated by the movement of a cartridge within the faucet. They can have one or two handles, and diagnosing issues often involves examining the cartridge itself and the O-rings that seal it. This type of faucet is known for its durability and ease of maintenance, as replacing the cartridge or O-rings usually resolves most leakage issues.

Ceramic-disk faucets, with their single lever over a wide cylindrical body, are the newcomers in the faucet family and are celebrated for their longevity and resistance to wear. The ceramic disks are nearly impervious to the deterioration that affects washers and cartridges, but they can still fall victim to sediment build-up or seal deterioration, which can cause leaks.

Ball-type faucets feature a ball assembly that adjusts the mixture of hot and cold water and controls the flow. It’s easy to identify them by their single handle that moves over a rounded ball-shaped cap right above the base of the faucet spout. The complexity of their mechanism often means that repairs may involve replacing worn O-rings, seals, or the entire ball assembly.

Tools You’ll Need

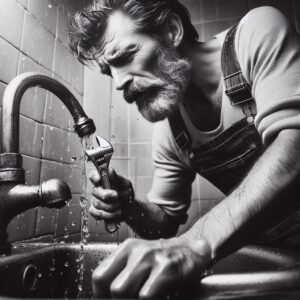

An adjustable wrench allows for the adjustment of its jaw width, making it suitable for turning different sizes of nuts, bolts, and fittings that you will encounter in various faucet models. The wrench’s versatility makes it a go-to tool for loosening and tightening the faucet’s components.

Screwdrivers are necessary for removing and securing screws that hold the faucet components together. The Phillips head screwdriver, characterized by its cross-shaped tip, and the flat-head screwdriver, with its single slot tip, can accommodate the majority of screws found in faucet assembly.

Penetrating oil, such as WD-40, is used to free up components that have become stuck due to corrosion or mineral buildup over time. A few sprays on the affected area can make the disassembly of parts much smoother.

Replacement parts are important items that you should have on hand before starting the repair. Depending on the diagnosis, these may include washers, O-rings, a cartridge, or seals, which are common components susceptible to wear and tear, leading to leaks. Identifying the exact replacement parts needed for your faucet type is a critical preparatory step.

Plumber’s grease is a non-petroleum-based lubricant used to ease the reassembly of faucet parts, ensuring they move smoothly against each other without sticking. Applying a small amount on O-rings and seals can aid both in the ease of reassembly and in extending the life of these components.

A clean cloth is useful for cleaning parts, wiping away dirt and sediment, and drying components before reassembly. Keeping the work area clean prevents foreign particles from causing further issues within the faucet mechanism.

Shut Off the Water Supply

The water shut-off valve is typically located underneath the sink. It’s a knob or lever that, when turned clockwise, ceases the flow of water to the faucet. In some instances, the shut-off valve may be situated in a basement or an outdoor location, especially in older homes or in cases where the plumbing system is centralized. It is advisable to familiarize oneself with the location of these valves ahead of any plumbing project.

Once the valve is located, gently turn it clockwise until it stops. Force should not be necessary, and over-tightening can damage the valve. After the water supply to the faucet has been discontinued, it is prudent to open the faucet to release any remaining water in the pipes. This action also serves to relieve any residual water pressure, ensuring a safe and dry workspace for the repair task at hand.

In homes where finding the local shut-off valve proves difficult, one must resort to turning off the main water supply of the house. While this effectively stops water flow to the entire home, it allows for safe faucet repair. This approach should be used sparingly, as it disrupts water access house-wide.

Disassemble the Faucet

Placing a cloth over the drain prevents small parts from accidentally falling into the pipeline, a simple yet effective measure to avoid unnecessary complications. With the workspace thus prepared, the focus shifts to the actual dissection of the faucet.

Using the appropriate screwdriver, begin by loosening the screws that hold the faucet handle or handles in place. These screws may be concealed under decorative caps that can be gently pried open, revealing the screws beneath. Patience is key here, as these components can sometimes be tightly fastened or may have become stiff over time.

Post the removal of screws, the faucet handle should be carefully lifted off. It is beneficial to pay close attention to the arrangement and condition of any additional components that become exposed, such as washers or cartridges, depending on the faucet type. Should these parts prove resistant to removal, applying a modest amount of penetrating oil can assist in loosening them by breaking down rust, corrosion, or mineral build-up that may be binding them in place. Waiting several minutes after application allows the oil to penetrate and ease the removal process.

A judicious approach to dismantling, marked by careful observation and documentation of where each piece fits, facilitates a smooth reassembly process. It is advisable to arrange the removed components in the order of disassembly or take notes, ensuring every part is returned to its rightful place, maintaining the integrity of the faucet’s design.

Inspect and Replace Damaged Parts

Focus on common culprits such as washers, O-rings, cartridges, or seals, depending on your faucet type. Washers, often found in compression faucets, are prone to wear out over time due to the constant pressure and friction they endure. Look for any signs of cracking, brittleness, or noticeable deformation in the rubber. O-rings should be examined for any signs of wear or degradation.

Focus on common culprits such as washers, O-rings, cartridges, or seals, depending on your faucet type. Washers, often found in compression faucets, are prone to wear out over time due to the constant pressure and friction they endure. Look for any signs of cracking, brittleness, or noticeable deformation in the rubber. O-rings should be examined for any signs of wear or degradation.

In cartridge or ceramic-disc faucets, the cartridge itself may become the source of leaks if it is damaged or if the material has begun to degrade. Visually inspect the cartridge for any signs of damage or wear. Sediment buildup on ceramic discs can compromise the faucet’s function, necessitating a careful cleaning or replacement of the discs or seals.

It is equally important to consider the age and wear of components that might not yet show significant signs of failure. Such proactive replacement can prevent future leaks and extend the faucet’s lifespan.

Once the damaged or worn parts are identified, acquiring the correct replacements is paramount. Always prefer manufacturer-recommended parts or exact-match aftermarket replacements to guarantee a successful repair.

Before installing new parts, it’s advisable to clean the faucet’s internal surfaces with a clean cloth, removing any debris or mineral buildup that could impair function. When installing the new components, applying a small amount of plumber’s grease to moving parts and seals can enhance operation and longevity.

Reassemble and Test

Reassembly should be approached methodically, reversing the order in which the faucet components were originally disassembled. Starting with the internal mechanisms such as cartridges, disks, or washers, each part should be securely placed in its respective position. It is important to ensure that new components, such as O-rings and seals, are installed correctly to avoid any misalignment that could lead to future leaks. Applying a light coat of plumber’s grease on moving parts can facilitate smoother operation and provide additional protection against wear.

Care should be taken to tighten screws properly, ensuring they are snug but not overtightened, as excessive force could damage the new components or the faucet’s finish.

The process of testing its functionality begins with gradually restoring the water supply. It is advisable to turn the shut-off valves slowly to allow water to flow back into the pipes gradually, minimizing any potential shock to the newly installed components. As water pressure is restored, observe the faucet for any signs of leakage.

Ensure that both hot and cold water are running smoothly and that the handles operate with ease. It is important to monitor the faucet for any drips or leaks during this time. Should there be a persistent leak, it may be necessary to disassemble the faucet again to check the installation of the components, as even a slight misalignment can result in leakage.

Testing the faucet’s functionality involves assessing the overall performance to ensure that the repair has restored the faucet to its optimal operation. This step is an affirmation of the quality and success of the repair work, providing peace of mind that the issue has been effectively addressed.